Grau Bambus Bodenbelag

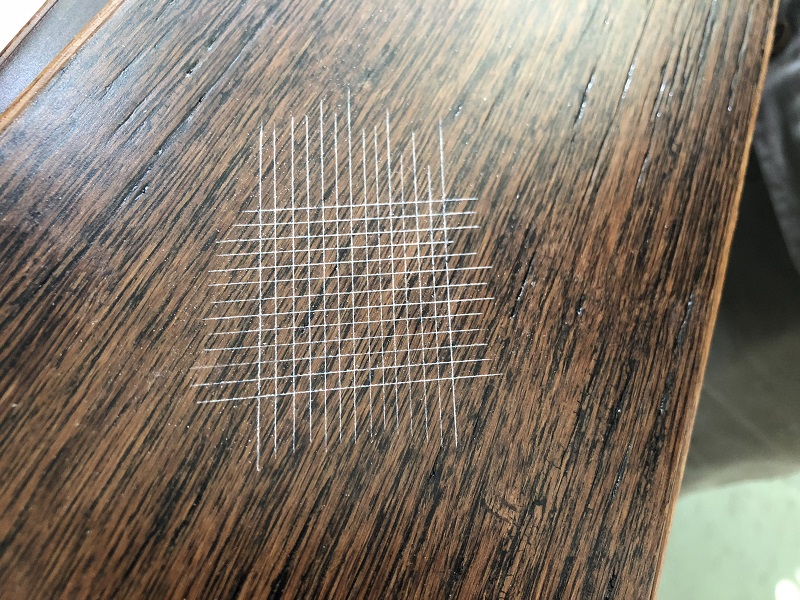

Carbonized Farbe Grau Gefärbten Bambus-Bodenbelag mit Draht-Oberfläche Gebürstet

Art.-Nr.:

SF-SWBA09Länge:

915/1850mmBreite:

125/130/135/140mmDicke:

10/12/14mmSchließsystem:

T&G, Unilin clickFertig:

UV CoatingKonstruktion:

Strand Woven Bamboo, Engineered BambooInstallation:

Nail down, Glue downGarantie:

25 years

Jede Diele ist für eine zusätzliche optische Textur einzigartig gealtert und ein Kunstwerk – sorgfältig von Hand gekratzt für ein natürlich gealtertes Aussehen und Gefühl.

visuelle Abschrägung

Visuell gebürstete Oberfläche

Ausgezeichnete Verschleißhaftung